Using Expanding Foam Around Heating Pipes

Expanding foam, like duct tape, has been compromised in more ways than you can imagine. Its original purpose was to seal small cracks in the wall, particularly those that are difficult to access.

But these days, among many other uses, expanding foam can be used to muffle the thumps coming from HVAC vents and to quiet noisy metal sinks.

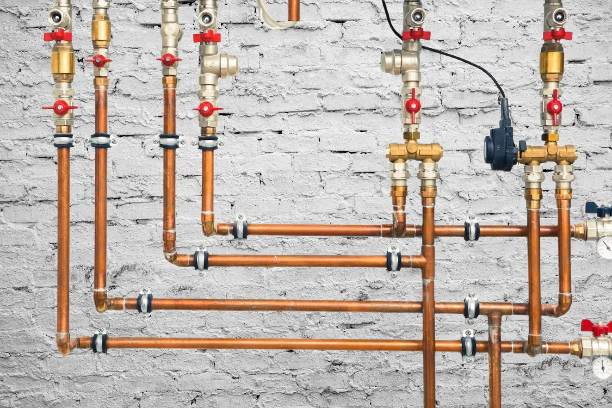

Expanding foam is also frequently used to fill in the spaces left by broken water pipes. Expanding foam can be very helpful if you detest the empty space left by pipes inside walls, are sick of rodents hiding there, or hear occasional rattling.

But as we are all aware, our homes have a variety of pipe types. Expanding foam can easily be used to fill in the spaces in regular pipes. You’re not entirely sure, though, if those are heating pipes.

Will the foam expand and be melted by the heat? Is it okay to put expanding foam right next to pipes that heat up? The use of expanding foam around heating pipes will be thoroughly explained in this article.

Is Expanding Foam Adequate for Encircling Heating Pipes?

The majority of expanding foams can be used safely in temperatures up to 240 degrees Fahrenheit. For residential water heating systems, a maximum temperature setting of 120 degrees Fahrenheit is advised. This indicates that the expanding foam can adjust to the temperature inside the pipes.

Only if the temperature in the heating pipes had been higher than what expanding foam could withstand would there have been a safety concern. Using expanding foam in this scenario would be unwise because it would have melted.

As can be seen from the above, filling the spaces around heating pipes with expanding foam is OK. However, before you apply the expanding foam around the heating pipes, you need to make sure of two things.

One thing to do is to make sure the expanding foam is at its highest temperature. The label will bear this information. Second, you need to know how hot your property’s heating pipes can get.

if the heating pipes’ temperature is lower than what the expanding foam can withstand. You are now free to continue. If it’s more, though, find another option as the expanding foam will melt and may release harmful gases.

Does Spraying Expanding Foam Require Insulating Heating Pipes First?

Spray foams are capable of absorbing heat from hot water pipes. As a result, there is zero justification for insulating the heating pipes prior to applying expanding foam.

You shouldn’t be concerned if you thought the expanding foam would melt as soon as the pipes heated up.

When Expanding Foam is exposed to continuous heat from the pipes, will it off-gas?

Since the heat generated is within the expanding foam’s operating range, we have already ruled out the possibility that using expanding foam near heating pipes is safe.

The fact that the heat in these pipes will remain constant is something that most people overlook. The expanding foam will come into contact with some heat each day.

You should anticipate the expanding foam to off-gas as the aforementioned occurs. Since polyol resin and isocyanate, two ingredients used to make expanding foam, are sensitive to temperature changes, it will be impossible to prevent this.

Once you’ve used expanding foam to seal the opening surrounding the heating pipes, after a while you will come to it. There is going to be a chemical odor.

You’ll be relieved to hear that the chemical off-gassing takes time to happen if that is a concern. In certain cases, the off-gassing may go undetected. However, if you’re still unsure, you should think about using mortar or plaster as an alternative.

The issue with mortar is that it will hasten the heating pipes’ deterioration, particularly if they are composed of copper. Each choice has benefits and drawbacks. It is up to you to decide which of the two best fits your tastes.

Is It Safe to Use the Expanding Foam Fire Retardant Around Heating Pipes?

It would be safer and even better if you could obtain expanding foam that is fire-resistant. This expanding foam is resistant to exposure to much higher temperatures than typical expanding foam. As a result, it ought to be resilient to the pipes’ heat.

Is It Appropriate To Apply Expanding Foam Near Heating Pipes?

Yes, and for the following reasons, in our opinion, expanding foam is a great filler for the spaces left by heating pipes.

Initially, heating pipes’ expansion and contraction can be accommodated by expanding foam. It’s quite simple to use. To fill the gap, all you need to do is spray it inside of it.

Second, once expanding foam reaches its maximum size, it can last for years if it isn’t exposed to UV light.

Expanding foam keeps your heating pipes rust-free longer than alternatives like mortar. If there is any rust, you need to check for leaks.

When expanding foam solidifies, can it harm heating pipes?

You can attest that expanding foam cure expands to approximately thirty to sixty times its original size if you have ever seen it in action.

You might be concerned about potential damage to your heating pipes as the material expands when sprayed on them. Expanding foam has the advantage of expanding in accordance with the available space.

It won’t harm any nearby copper pipes if any exist. Rather, it will expand all around them to ensure that they are fixed and no longer rattling.

How Can Expanding Foam Be Used To Seal Gaps Around Heating Pipes?

Perhaps someone will mention how simple it is to use expanding foam. However, if this is something you have never done before, it may seem a little daunting at first.

Here’s a quick guide on using expanding foam to fill gaps around heating pipes so you know what you’re doing.

- Step 1: Purchase some high-quality expanding foam. While Big Gap filler and TITE FOAM are two other expanding foams, most of you are probably familiar with Great Stuff. Any of these choices can produce long-lasting effects.

- Step 2: Set up the workspace. Cover the immediate vicinity first. Working with expanding foam can occasionally be quite messy. Make sure there is no grease and that all loose materials are removed to extend the project’s lifespan.

- Step 3: Use some water to dampen the surface. This aids in the curing process of the expanding foam.

- Step 4: Give the can a good shake to make sure the contents are evenly distributed. The spray applicator gun that is packaged with the expanding foam should then be attached. In the crevice surrounding the heating pipes, begin spraying the foam.

Recall to periodically shake the can. Don’t be afraid to exert additional pressure when needed. When it comes to the expanding foam, be sparing. There could be a major mess on your hands.

- Step 5: Allow the expanding foam to cure for 24 hours after you’re satisfied that it’s enough. To make sure the gap is invisible, you can trim, sand, and even paint over the foam once it has cured. We advise using a filler to ensure a smoother finish before painting over it.

Does Expanding Foam Handle Heat Well?

It is essential to take into account the product’s heat resistance when using expanding foam in areas like around heating pipes.

As previously stated, the majority of expanding foams have a higher heat resistance than pipes that are heated. Because of this, there are no issues when the two coexist.

It’s critical to understand that expanding foam has a limited capacity to withstand heat. Most expanding foams have a maximum heat resistance of between 200 and 300 degrees Fahrenheit.

Expanding foam should not be used if the temperature is higher than that range. Essentially, the conclusion is that expanding foam has a limited heat resistance. When expanding foam is exposed to a lot of heat, it will melt and release fumes.

When Is Expanding Foam Not Appropriate to Use?

Now that we know that expanding foam works well around heating pipes, it’s important to include a list of other places where you shouldn’t use this material.

Expanding foam has many uses, but it’s important to understand its limitations.

- In electrical box areas or nearby.

For whatever reason, avoid spraying expanding foam near or inside electrical boxes. Not only can this damage electrical components, but high temperatures can also cause expanding foam to catch fire.

- Refrain from covering windows and doors with high expansion expanding foam.

Expanding foam comes in two primary varieties: low and high expansion. The latter is not recommended for confined spaces. It can expand and cause the window or door frames to pop when applied to doors.

- Never attempt to fix heating pipe leaks over the long term with expanding foam.

Let’s say there is a leak in your heating pipes. Either immediately fix them or contact a licensed plumber. Expanding foam works well for temporary fixes, but not for long-term ones.

Leaks continue even after expanding foam has been sprayed. It simply slows it down, that’s all. When the water spreads to other areas, internal wall damage starts to happen. There will also be mold growth.