Construction Safety: Key Rules and Practices

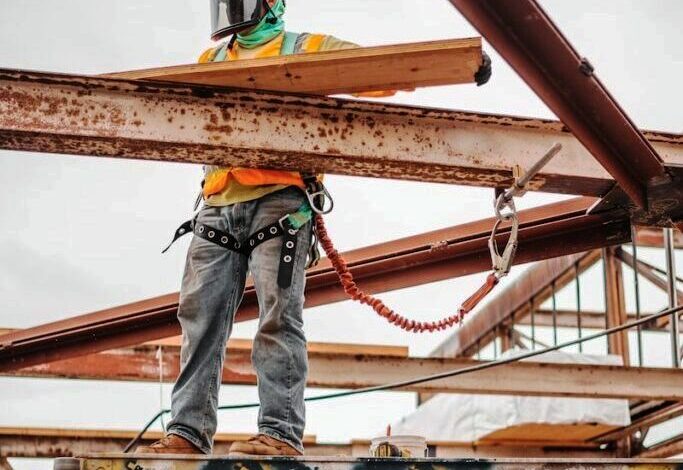

The general safety guidelines for construction sites listed below should be adhered to in order to prevent accidents, injuries, and other health issues for both workers and visitors:

1. Put on protective gear at all times

To lessen their exposure to potential risks, all employees and guests at the construction site should wear the appropriate personal protective equipment (PPE). PPEs that are frequently used include high visibility vests and suits, goggles, helmets, gloves, boots, and earplugs or muffs.

2. Pay attention to signs and exercise caution

Signs pertaining to safety enable managers to issue alerts and increase workers’ and guests’ awareness of health and safety. When needed, arrange them in the proper locations throughout the site. The various safety signs and instructions for construction sites, such as those pertaining to firefighting equipment, warning signs, prohibition signs, and mandatory signs, should be understood by workers.

3. Give precise directions.

There should be a general contractor site induction present. This will facilitate the familiarization of new employees with site operations.Another efficient method of delivering health and safety guidelines to employees is through toolbox talks. Either daily or more frequently, it is done prior to work starting.

4. Maintain a clean site

Make sure that the area is clear of any dust, debris, loose nails, and standing water from backfilling and excavation. To avoid trips and falls, the construction site needs to be kept clutter-free and cleaned every day.

5. Properly arrange and store your tools.

Make sure all tools are put away, and unplug any lights and power tools. Adhering to construction site regulations can aid in preventing tool damage and potential worker injuries. Ensuring that they are arranged appropriately will facilitate effortless navigation as well.

6. Match the appropriate tools to the appropriate task

Misuse of tools or equipment is a common cause of accidents. Steer clear of using homemade tools. Instead, to complete the task more quickly and safely, use the appropriate tool.

7. Maintain a plan for responding to emergencies

The workforce is instructed on what to do in the event of an emergency, such as a fire, hazardous material spill, or other incident, by means of an emergency response plan. Establish a specialized team to handle emergency situations, respond to inquiries, and report any dangers, problems with quality, or near-miss incidents.

8. Install safety measures

Putting engineering controls like fences, barriers, and safeguards in place is one method to guarantee safety on the job site. They’ll assist in keeping people away from potentially dangerous locations like high-voltage electrical systems or compounds that emit harmful fumes.

9. Examine tools and equipment beforehand

Make sure the tools and equipment you’ll be using are in good condition before you start working.

10. Report problems right away

Teach employees to report flaws and near-misses as soon as they are discovered on the job site. Only after problems are brought to management’s attention can they be resolved. There is less likelihood that problems will worsen, leading to mishaps or additional harm, the sooner they are reported.