Common Concrete Uses in Construction

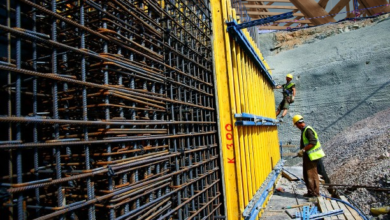

The most widely used building material in the sector is concrete. Concrete is a thermal mass material made of a mixture of fine aggregate, cement, water, gravel, and stones rather than being made of a single material. These materials are used in the construction of superstructures as well as the foundation of many other structures. Concrete is used, for instance, in structural concrete, stair construction, and slab construction through architectural features. So how is concrete applied in building projects?

Basic foundations, external surfaces, superstructures, floor construction, wastewater treatment facilities, and parking lots/structures are all made of concrete. Cement quality is determined by a number of factors, such as consolidation, appearance, and placement accuracy. While these three are significant, concrete quality extends far beyond them.

When the team specifies the right dimensions required for the support structure, ingredients for the concrete mix design, finish details, and constructible work specifications, the quality of the concrete is evident from the outset. Together with building concrete, it’s critical to fully comprehend the needs for accessories, historical data on comparable materials, appropriate material placement, achievable strengths, and methods for routinely monitoring the strength of designs.

In terms of composition and structure, concrete is comparable to mortars.

Even in extreme and unfavorable circumstances, concrete has an incredibly long lifespan. For extended periods, concrete can withstand abrasion, chemical reactions, weathering, tensile stresses, and comprehensive stresses. Concrete structures are better suited for environments with harsh conditions because of their resistance to these actions.

Concrete’s characteristics

Concrete’s qualities make it a great material for construction. The strength of concrete comes from the material components in the concrete mix; concrete is made of very strong materials that can withstand high tensile and overall stresses without breaking.

Consolidation and reinforcement coverage are critical for the prevention of in-place work from needing to be fixed or removed during the concrete production process. It’s critical to plan ahead before actual construction starts to ensure that the project has the tools and supplies needed to deliver the best possible result for the client. Additionally, precise work raises the standard of quality in concrete structures, making it possible for other trades to install and finish their work correctly.

Concrete can be combined with various components and materials for construction. Solidify using the subsequent:

- Concrete-supporting structures

- Points of anchorage for structural steel

- Add-ons like masonry reinforcement, embedded steel reinforcement plates, reinforced concrete couplings, and support for building masonry façades

Concrete Types

Crushed aggregates, water, and concrete mix are the ingredients of pervious concrete, a kind of structural concrete pavement. Because it is energy-efficient and absorbs water instead of letting it pool, pervious concrete is crucial to the green construction movement. This naturally filters soil and lowers water pollution.

Prestressed concrete: As per the Portland Cement Association, prestressing concrete eliminates the load, span, and permit restrictions associated with conventional concrete for walls, floors, roofs, and bridges. Prestressed concrete enables designers, engineers, and contractors to create structures made of lighter concrete without sacrificing structural integrity.

How to Locate a Concrete Builder

- Make an investigation

- Request referrals

- Put everything in writing and evaluate costs.

- Obtain the necessary permits.

- Assess the interactions you have.

- Get a reference list please.

- Seek out prior experience

- Check the Insurance

FAQs: How Construction Projects Use Concrete

- What typical applications does concrete have in building projects?

Concrete is used in many different aspects of construction, such as parking lots and structures, superstructures, exterior surfaces, floor construction, and wastewater treatment facilities. In these applications, it acts as a basic building block.

- What elements affect the concrete’s quality in building projects?

Accurate placement, appearance, consolidation, suitable dimensions, concrete mix design, finish details, and constructible work specifications are some of the factors that affect the quality of concrete. Achieving quality also requires a thorough understanding of the necessary accessories, past data on related materials, material placement, achievable strengths, and strength monitoring techniques.

- What is the composition and structure of concrete in comparison to mortars?

In terms of composition and structure, mortars and concrete are similar. Concrete, on the other hand, is a stronger material that can endure comprehensive and tensile stresses over time, making it appropriate for a variety of construction applications.

- Which varieties of concrete are utilized in building projects?

Pervious concrete and prestressed concrete are two prominent varieties of concrete. By absorbing water and naturally filtering soil, pervious concrete helps build environmentally friendly structures and lowers water pollution. Prestressed concrete gives engineers and architects flexibility by enabling lighter building designs without sacrificing strength.

- For my construction project, how can I locate a trustworthy concrete contractor?

It takes a number of steps to find a reliable concrete contractor: research, asking for referrals, getting written contracts, comparing quotes, confirming insurance and licenses, calling references, assessing experience, and making sure all relationships are in order. These guidelines assist you in selecting a reliable contractor.